|

COMPANY

|

| .Our Company |

| .Company Vision |

| .Our Services |

|

PRODUCTS

|

| .Products |

| .Specifications |

| .Approvals |

| .Downloads |

|

CONTACTS

|

| .Plant Natal |

| .Sales São Paulo |

| .Resales |

|

LANGUAGE

|

| .Portuguese |

|

E-MAIL

|

| .Plant Natal |

| .Sales São Paulo |

.....................................

|

RESITEL®

É Polyurethane Resins BLOCKING

|

|

PRODUCT INFORMATION Advantages over other Polyurethane systems:

These resins do not corrode in contact with copper and are compatible with all materials that are mostly used in electric equipment. RESITEL resins have been widely accepted in Telecom and E/E industry. Most frequent applications are: pressure blockage and telephone cables splicing, voltage regulators, transformers, capped cables, circuit covers, transistorized ignition systems and impact absorbers |

|

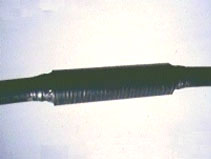

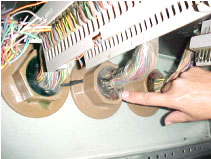

Application Pictures

|

|

|

|

SPECIFICATIONS RESIN RESITEL®

|

|

RESITEL® 001

Pressurization Blocking |

Liquid form.

Used in blockage and pressurization of telephone cables. Also

used in electronic circuits that are resin filled.Color: amber.

Ideal for cables with paper lining (CT-APL)

|

| Polyol : Prepolymer ratio | 1 : 0,4 |

| Gel Time @ 25°C (ASTM D - 2471) | 10 - 45 min |

| Cure Time | < 24 hours |

| Max. Cure Temperature (ASTM D - 2471) | <80°C |

| Density (20°C ) (ASTM D - 792) | 0,9 - 1,0 g/m |

| Initial Mixture Viscosity (ASTM D-2669) | 400 - 600 cps |

| Hardness (ASTM D - 2240) | 50 - 90 Shore "A" |

| Water Absorption % (ASTM D - 570 ) | 1,0% |

| Volumetric Resistivity (ASTM D-257) | 10 |

| Dielectric Constant @ 25°C (ASTM D - 150) | 10 |

| Dissipation Factor (ASTM D - 150) | 10 |

| Insulation Resistance (ASTM D-257) | 10 |

|

RESITEL® 003

Pressurization Blocking |

Differs from

Resitel 001due to its higher hardness linked to a lower viscosity.

This allows a better flowability in cables of plastic lining.

Type (CTP-APL)

|

| Polyol : Prepolymer ratio | 1 : 0,50 |

| Gel Time @ 25°C (ASTM D - 2471) | 20 - 40 min |

| Cure Time | < 24 hours |

| Max. Cure Temperature (ASTM D - 2471) | 80°C máx. |

| Density (20°C ) (ASTM D - 792) | 0,9 - 1,0 g/cm |

| Initial Mixture Viscosity (ASTM D-2669) | 1000 - 1200 cps |

| Hardness (ASTM D - 2240) | 60 - 85 Shore "A" |

| Water Absorption % (ASTM D - 570 ) | 1,0% |

| Volumetric Resistivity (ASTM D-257) | > 10 |

| Dielectric Constant @ 25°C (ASTM D - 150) | 10 |

| Dissipation Factor (ASTM D - 150) | 10 |

| Insulation Resistance (ASTM D-257) | 10 |

|

RESITEL® 003 ARD

Pressurization Blocking ..(low viscosity) |

Low viscosity

resin used to block out moisture and pressure. It is applied using

gravity method. Mostly used in cabinet cubicles, cabeçotes

and CBTP kit's with pressure outlets.

|

| Polyol : Prepolymer ratio | 1 : 0,42 |

| Gel Time @ 25°C (ASTM D - 2471) | 30 - 50 min |

| Cure Time | <24 hours |

| Max. Cure Temperature (ASTM D - 2471) | 80°C máx. |

| Density (20°C ) (ASTM D - 792) | 0,9 - 1,0 g/cm |

| Initial Mixture Viscosity (ASTM D-2669) | 1000 - 1850 cps |

| Hardness (ASTM D - 2240) | 40 - 85 Shore "A" |

| Water Absorption % (ASTM D - 570 ) | 1,0% |

| Volumetric Resistivity (ASTM D-257) | > 10 |

| Dielectric Constant @ 25°C (ASTM D - 150) | 10 |

| Dissipation Factor (ASTM D - 150) | 10 |

| Insulation Resistance (ASTM D-257) | 10 |

| | |

...................

...................